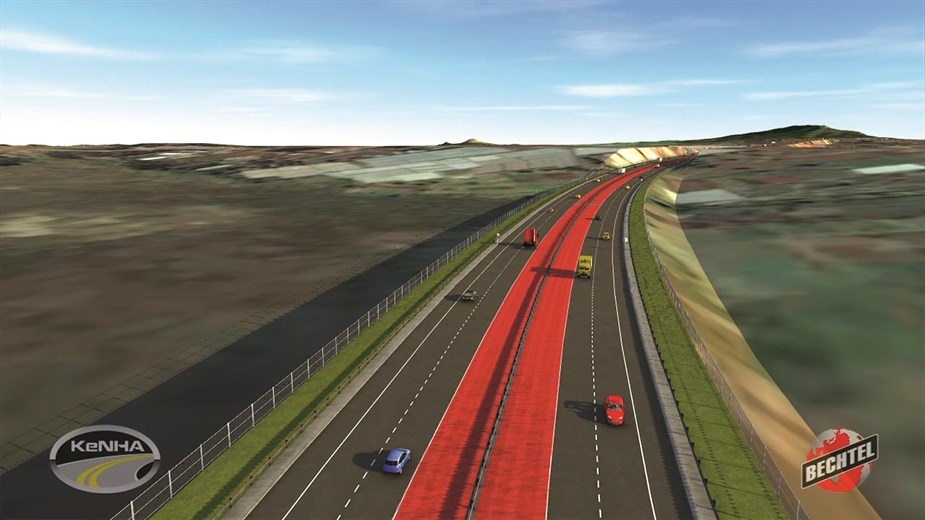

The construction of the much anticipated Nairobi-Mombasa expressway is scheduled to kick off in July this year. The project is awarded to Bechtel, an American engineering contractor. On completion the project is expected to greatly benefit to Kenyans and the whole country.

Plans for the region’s first high-speed motorway are in final stages to pave way for actual construction work to start. The motorway measures about 473 km.The project is expected to cost US $3bn. Additionally, the Nairobi-Mombasa expressway will reduce travel time between the two Kenyan cities by up to 50%. Bechtel top officials estimate that the road project will generate nearly twice the money spent on the project over a period of 25 years.

Kenya needs a public-private-partnership (PPP) approach on the road construction project, such that under this model, the firm will source financing and build the road, then operate it for a number of years during which it will charge motorists for its use. Bechtel is inclined to the EPC model, advising that the alternative public private partnership (PPP) would cost five times more at US $15bn and it will take longer to complete.

Transport CS James Macharia said: “The ministry is yet to settle on a model of financing the road, however, we would prefer a public-private-partnership.” Plans for the Nairobi-Mombasa expressway come shortly after Kenya unveiled the Standard Gauge railway line aimed at decongesting the busy road. Furthermore, the East African country hopes that the mega infrastructure projects currently ongoing will help open up the country and boost trade.

Committed to support Africa’s economic growth, Bechtel opened a regional Africa office in Nairobi last year.

More news

- CELEBRATING EXCELLENCE IN THE RESIDENTIAL PROPERTY SECTOR

- PART 4: GIBS PANEL DISCUSSES INTEMEDIATE CITIES ROLE IN AFRICA’S DEVELOPMENT

- EXPOSED AGGREGATE PAVERS COMPLEMENT NEW LIFESTYLE CENTRE

- GIBS PANEL EXPLORES ROLE OF INTERMEDIATE CITIES IN SA’S DEVELOPMENT PART 3

- CITI-CON’S CONCRETE KNOWLEDGE SUCCESSFULLY DEPLOYED ON NEW LANDMARK DEVELOPMENT