Mapei is best-known for its vast range of

construction chemicals, admixtures and adhesives, yet few realise that it’s

influence begins far earlier in the construction cycle with the provision of

advanced chemicals that aid cement manufacturers in the production of

high-quality cement.

In South Africa, and worldwide, Mapei is a

major supplier of cement additives and grinding aids that improve the

characteristics of cement, enabling producers to increase throughput and so

achieve better efficiencies and lower costs per ton of cement sold.

Mapei product manager for cement additives,

Laurence Gopane, says cement is produced with a complex recipe of clinker and

other ingredients including gypsum, fly ash, slag and limestone amongst others.

Each additive is tailor-made for each plant to support the particular

ingredients and manufacturing processes.

Careful selection

“Regardless of the mix, even plants within the

same organisation may have different recipes with their own unique challenges.

That’s where our team comes into its own. We are able to partner with the producer

and recommend products that will assist in meeting the specific requirements,”

adds Gopane.

“For example, some additives are grinding aids

that improve the grinding action of the mills by preventing particle

agglomeration and adhesion to equipment; and there are different types

available that improve the strength of performance. Mapei Grinding Aids

(M.A.G.A) as well as performance enhancers (M.A.P.E) influence the properties

of the final cement. Producers are therefore able to “tweak cement” to have

different properties, such as optimising early strengths and late strength

gains etc.

“The country’s major cement manufacturers rely

on these additives to achieve their production goals. Needless to say, since

Mapei’s entry into the local market some ten years ago, the game has changed

and our modern additives have brought many advantages to the market that

ultimately improves the quality of cement to end users,” says Gopane.

Live tests

He explains that due to the technical complexity

of the cement manufacturing process, there are many different variables that

need to be considered when adding additives. These include the type of clinker

being used, mix ratios of slag, fly ash, and other ingredients, as well as

equipment type, grinding media and a host of other variables.

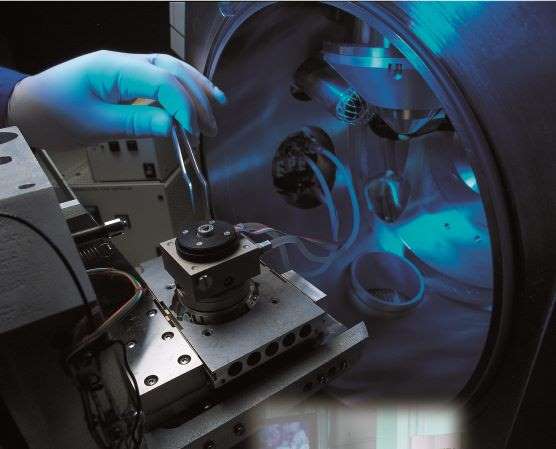

The selection of the cement additive starts

with lab testing of the specific raw material.

This usually results in an initial prototype of

grinding aids, which is then tested in the mill and adjusted according to the

actual outputs and requirements. In the end, however, the result is the best

possible product that can be produced cost-efficiently from each manufacturing plant.

And, for the end user, it results in the best quality cement at the best

possible price per bag or ton.

“For contractors and other users – the use of

quality cement is critical in producing high quality concrete for local building

sites. It also enables cement producers to keep up with the high demand for

quality cement in either bulk or bags. This is when our team from Concrete

Admixtures will be able to add further technical support and benefits,” Gopane

concludes.

Giving back

Mapei also hosts an annual Cement Additives

Seminar which is open to all cement producers and blenders; regardless of being

a current customer or not. Specialists and technical consultants from our C-ADD

division in Milan come out to South Africa to interact, educate and present

relevant content to the attendees about the Cement Additives industry. The

event sheds light on the latest best practices, technologies and products

available to help cement producers to keep up with new and challenging demands.

The 2020 Cement Additives Seminar is anticipated to take place during the

second quarter of 2020.

More

information from Geoffrey Green, Tel:

+27 11 552 8476 / email: [email protected]

www.mapei.co.za