“Konecranes recently installed their C Series electric chain hoist at a local rail company’s brake and motor assembly line. The C Series chain hoist will be utilised in conjunction with a jib crane at the assembly workshop and was required to give a lifting capacity of 320 kg. The C Series was only recently launched in South Africa, so we are particularly delighted to see it in action on a production floor so quickly. Konecranes, through the advanced features of the C Series, now offers customers a state-of-the-art electric chain hoist that will make a major difference at customer’s lifting facilities”.” said Emil Berning, Managing Director, Konecranes, South Africa.

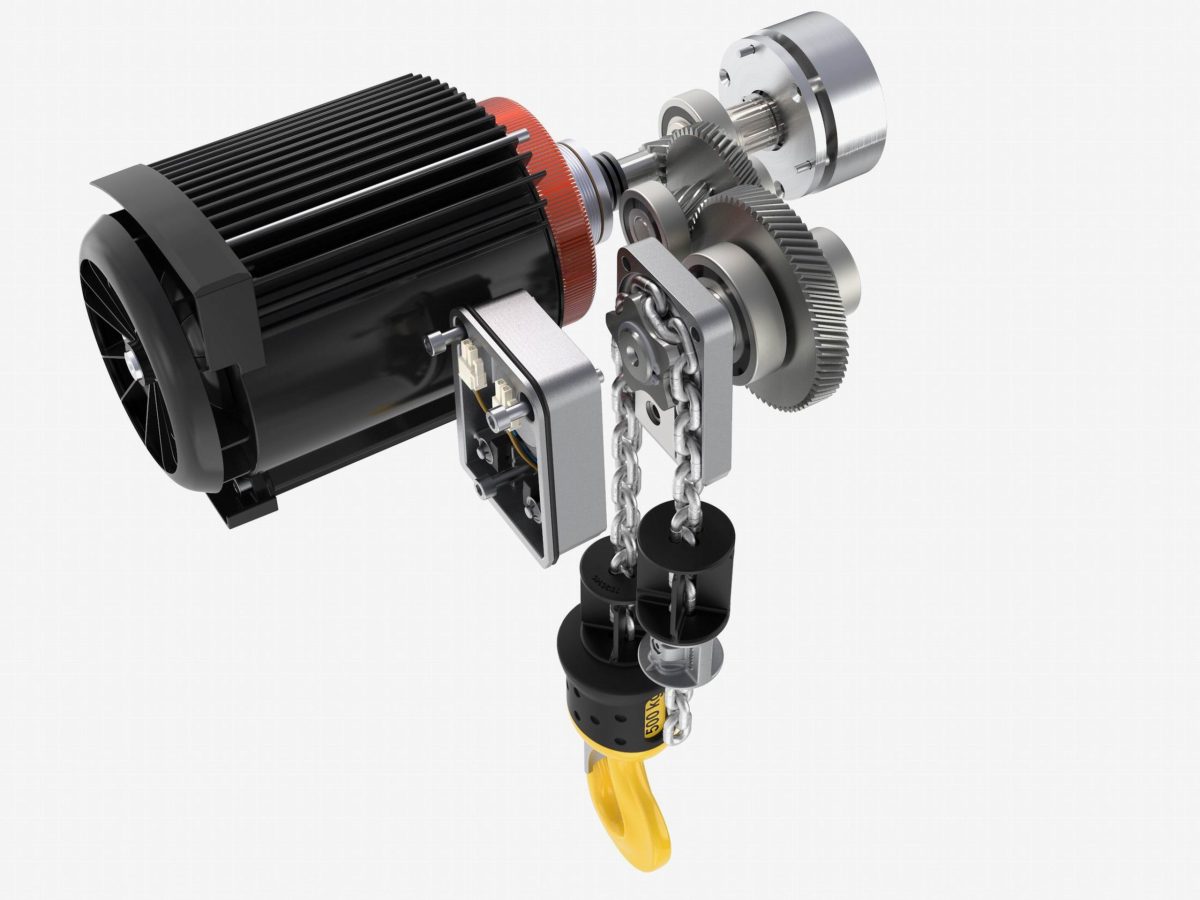

The local rail company had been looking for a new electric chain hoist that could offer greater safety features, more production reliability and uptime while keeping maintenance stoppages to a minimum and being cost efficient. The hoist boasts a redesigned motor cooling system, offers up to a 50% longer runtime and a brake built for over a million operations. Improved safety features comprise an operating limit switch and safety clutch that have been enhanced for a safer and better performance and reliability.

The C-series has been ‘built smart’ with the precision and reliability of the company’s Core of Lifting components. It is the most advanced electric chain hoist available, offering a lifting capability of up to 5,000 kg. The C-series brings more control and mobility to working areas due to its more compact hoist shape.

In another coup for Konecranes, Italian-based InoxPlus, who assemble and handle stainless steel and electromechanical components for the construction and machinery industries, recently took possession of a Konecranes S Series overhead crane with a newly designed Compact Box. The S Series crane includes Konecrane’s unique synthetic wire rope hoist. The synthetic wire rope hoist gives a barb free operation, safer handling and easier load carrying as well as reduced maintenance costs.

The S Series with the Compact Box offers benefits such as outside welds for ease of inspection, a sliding connection for smooth movement on runways. The synthetic rope suits InoxPlus’ applications by giving a

gentler handling of steel sheets and a cleaner operation. Compared to conventional ropes, the synthetic rope has a superior resistance and lifespan. The Konecranes Compact Box is a new main girder type with a modular structure making transportation far easier. Precision and the rope angle features were other elements of the S Series overhead crane that impressed InoxPlus.

The S Series overhead crane has application from aerospace to laboratory clean rooms and engine assemblies, in fact practically every manufacturing industry requiring reliable and cost-efficient crane equipment.

Berning said “Konecranes has always subscribed to the philosophy that continuous investment into research and development will deliver the desired improved performance and enhanced safety where the customer requires it most, in operation on the factory floor. Our cranes and associated lifting equipment offer just that, across the range”.

“The C Series electric chain hoist and the S Series overhead crane with synthetic rope are but two of our latest unique and innovative offerings. Our synthetic rope hoist is now the benchmark in the industry. Through a major re-design, our S-series gives a stepless hoisting movement and the synthetic wire rope makes lifting more precise with enhanced control”.

“Despite the current restrictions impacting upon live demonstrations of cranes and rope hoists, we are on track to be able to offer our customers ‘online live crane demonstrations’ via our newly launched Live Channel shortly. Another Konecranes innovation” concluded Berning.