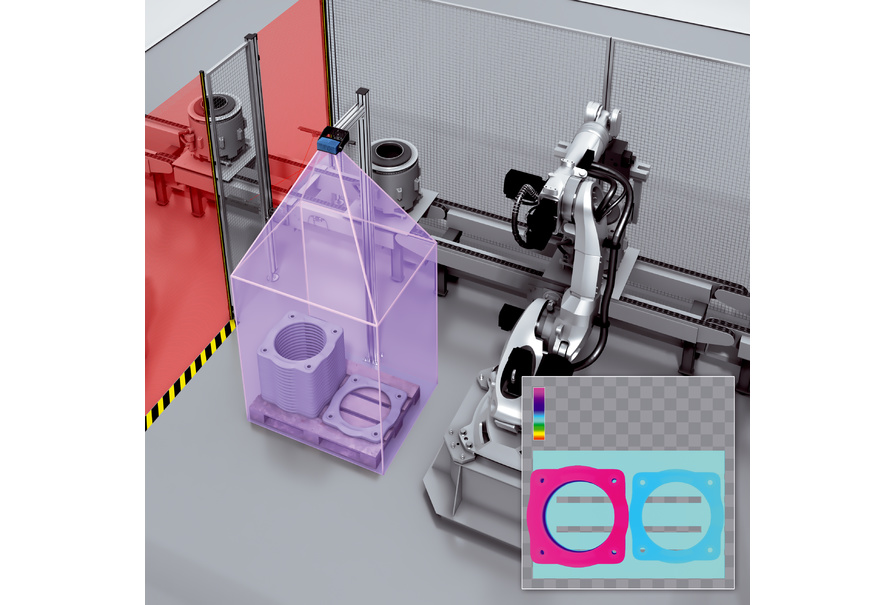

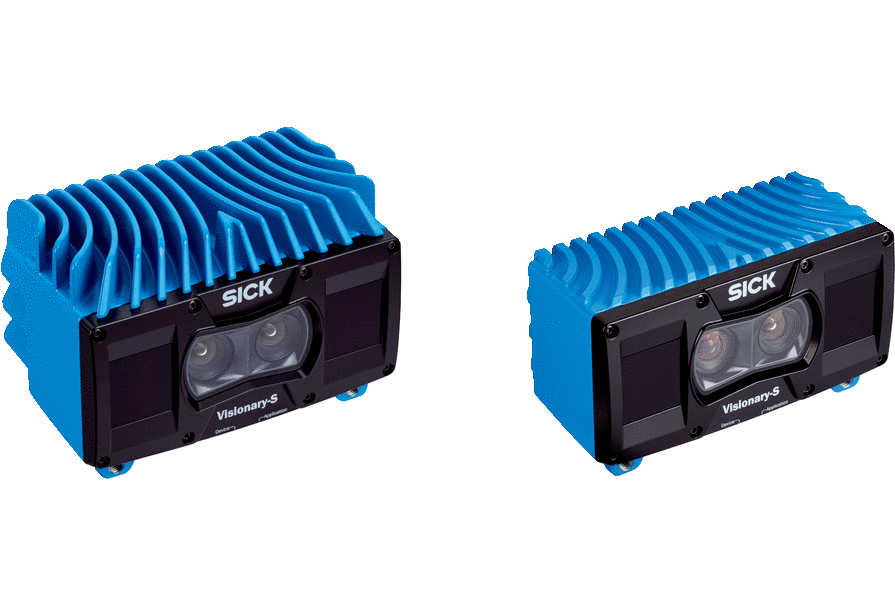

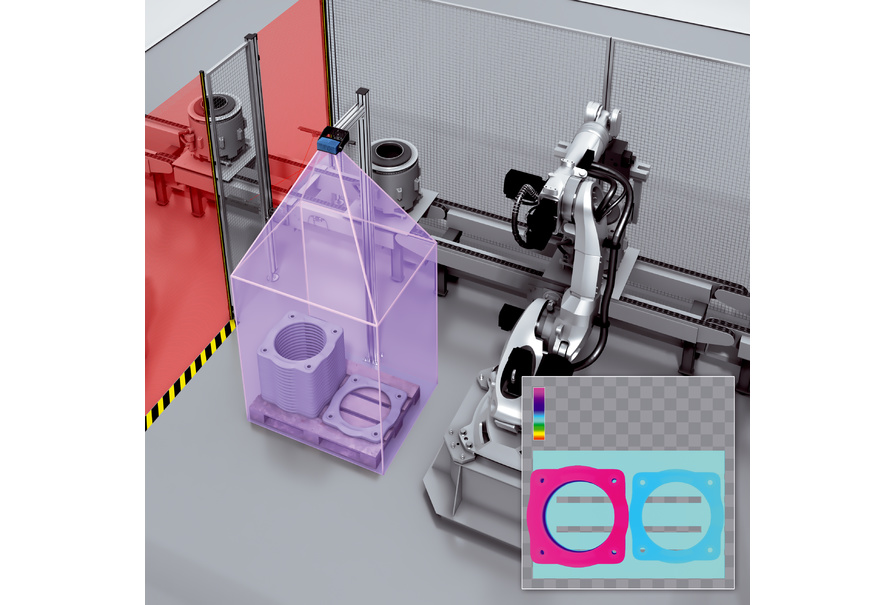

SICK Automation, a leading producer of sensor automation solutions, now offers local industries a 3D machine vision camera that enables automated management of products or goods in any factory or warehouse environment. Called the Visionary-S CX, it integrates with robotic handling systems (e.g. depalletisation or picking systems) or quality control solutions to enable the real-time identification, picking, and selection of goods accurately and quickly for highly optimised warehouse or production operations.

The Visionary-S CX is a rugged camera with the ability to “see” both colour and depth, as well as dimensions, even in environments with low ambient light. This means it recognises items and objects reliably, giving it the ability to identify and select individual products in densely packed boxes, for example. It also features a high recording speed, making it effective in high-speed applications. It integrates easily into existing systems using system integration (SI) software, to enable prompt optimisation. The easily configurable input and output functionality of the Visionary-S CX makes it versatile and flexible.

Previously, robotic carton handling or quality control packaging systems were limited by 2D technology. A robot could be programmed to pick or select an item, that was positioned at specific position-coordinates on a pallet, a table, or conveyor belt. If the item was not in that exact location (or not positioned accurately, at the optimal height or depth) the system failed. “The Visionary-S CX, essentially gives the robotic system human vision that identifies target items and understands where these are,” explains Grant Joyce, Managing Director, SICK Automation Southern Africa.

The Visionary-S CX solution was recently applied in the Belgium-based warehouse of a pharmaceutical company, where it optimised the depalletisation and picking of cartons, enabling the system to detect cartons at a rate of 2 000 per hour and depalletise them rapidly. As a result, the company was able to meet high demand for its products across Europe. “Through collaboration with our SI partners, we are able to build complete application solutions such as this for customers in southern Africa,” adds Joyce. Designed to deliver easy installation, programming and commissioning, the Visionary-S CX is also priced competitively for the local market.

About SICK Automation

SICK Automation Southern Africa, is a wholly owned subsidiary of SICK AG, headquartered in Waldkirch, Germany. SICK is one of the world’s leading producers of sensors and sensor solutions for industrial applications. SICK offers high-quality sensor technology and solutions as well as applications, system integration and service expertise for the factory automation, logistics automation and process automation industries.