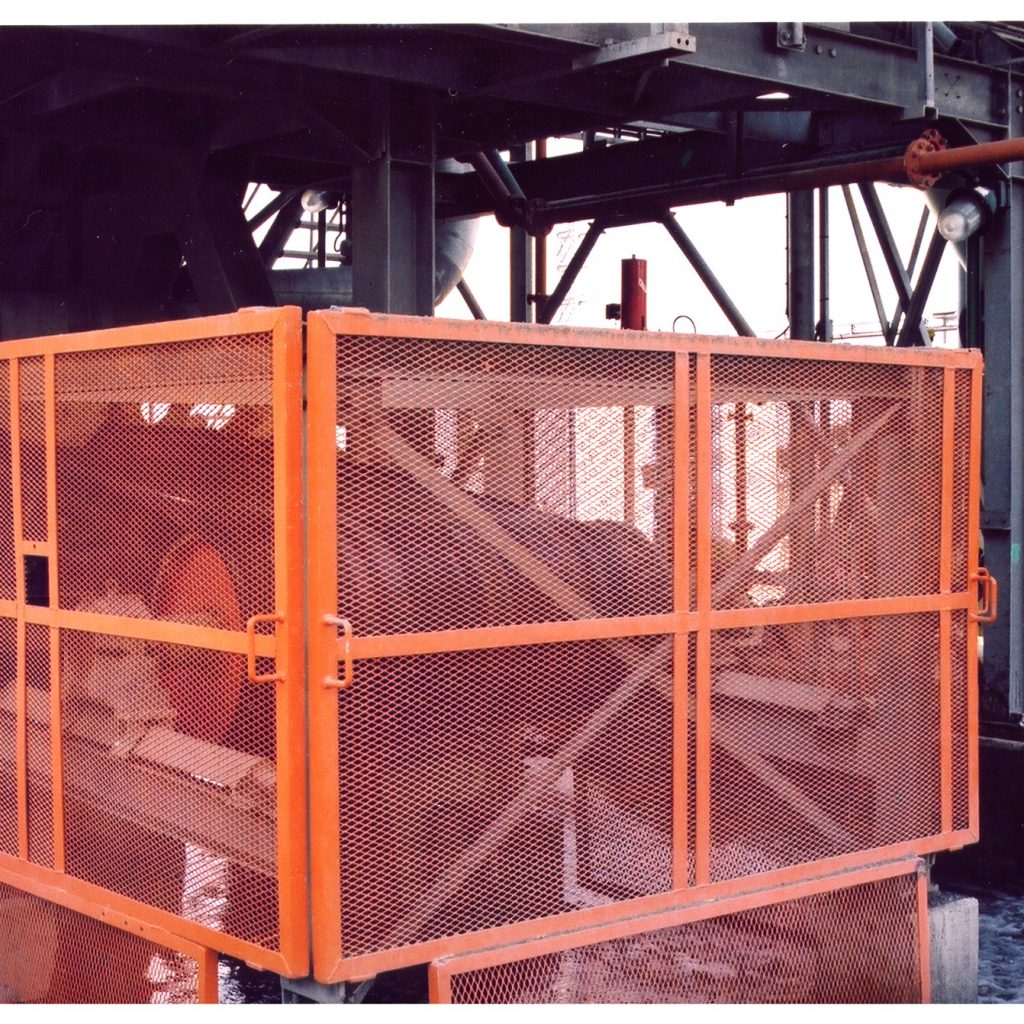

Durable, dependable, and incredibly versatile, Mentis Expanded Metal continues to be an economical and cost-effective material. The manufacturing process ensures optimum material integrity and strength and allows it to be used for a wide range of applications.

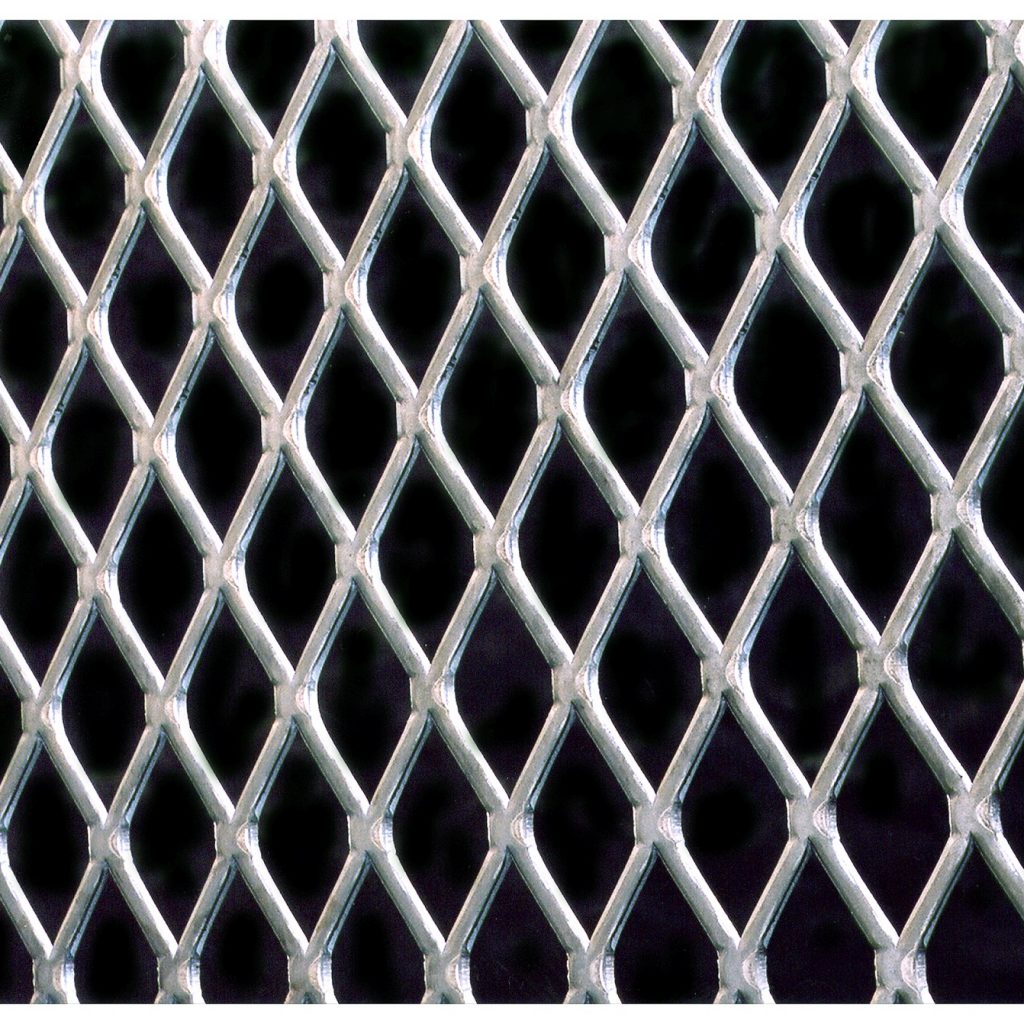

Ruben Roach, COO of Mentis Africa, one of the country’s foremost engineering and manufacturing companies based in Elandsfontein, explains that the material is made by slitting and expanding a solid sheet of metal into a web of diamonds.

“The metal sheet can, in fact, be expanded up to ten times its original size, losing no material in the process and resulting in a remarkably light mesh,” he says. “And expanded metal offers flexibility because it is available in a variety of sizes and materials.”

Lighter, stronger, flexible

One of the most important features of expanded metal is its inherent structural integrity and strength. Roach says this, facilitated by the network of rigid strands, also permits light and air to pass freely through it. The final product is also lighter per metre and stronger per kg than its original sheet.

High quality local mild steel is used in the manufacturing process, but any other ductile metal such as aluminium and stainless steels are also suitable. The finished product can be painted, stove-enamelled, plated, and galvanised. The company produces expanded metal with a raised mesh, known as Mentex, and with a flattened surface, known as Flatex. Roach says that the most appropriate type of expanded metal differs for each intended application for which the material will be used. Expanded metal even provides opportunities for innovative architectural designs.

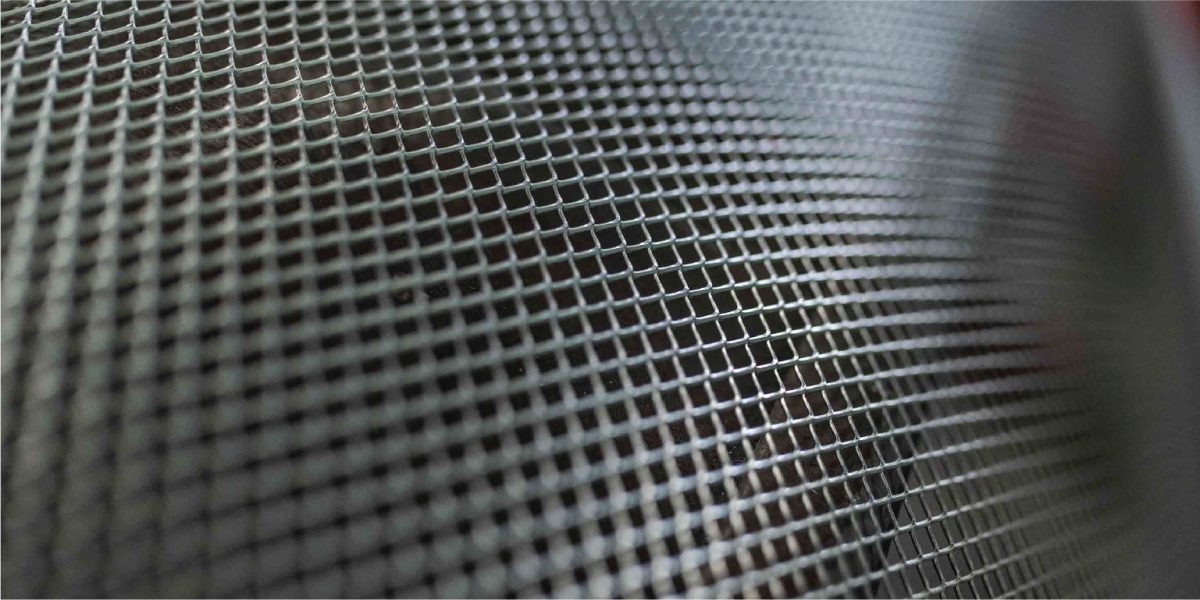

The range of mesh sizes and thicknesses of both Mentex and Flatex is extensive and the expanded metal can be bent, shaped to radii, angled, or notched. Customers can select a broad spectrum of mesh sizes, from the smallest mini-meshes with openings of 2 mm by 4 mm and a thickness of 0,4 millimetres to the larger versions with openings of 75 mm by 200 mm and a thickness of 6 mm.

More news

- CELEBRATING EXCELLENCE IN THE RESIDENTIAL PROPERTY SECTOR

- PART 4: GIBS PANEL DISCUSSES INTEMEDIATE CITIES ROLE IN AFRICA’S DEVELOPMENT

- EXPOSED AGGREGATE PAVERS COMPLEMENT NEW LIFESTYLE CENTRE

- GIBS PANEL EXPLORES ROLE OF INTERMEDIATE CITIES IN SA’S DEVELOPMENT PART 3

- CITI-CON’S CONCRETE KNOWLEDGE SUCCESSFULLY DEPLOYED ON NEW LANDMARK DEVELOPMENT