Demand for middle-income housing in Polokwane still remains high long after the city was named the capital of Limpopo.

This demand is mainly being driven by civil servants, who prefer their own homes to rental accommodation, while the conversion of existing residences into commercial buildings in Polokwane has compounded the shortage of housing stock.

As such, new residential suburbs located just outside the central-business district are developing at a rapid rate. This includes Serala View, one of the “Place of Safety’s” newest suburbs that comprise more than 700 available residential stands in Polokwane Extension 28.

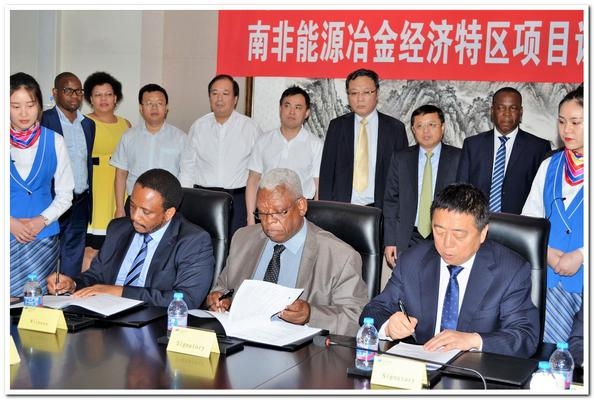

The Development Bank of Southern Africa committed over R50-million to this major housingproject in a loan agreement with Polokwane 28 Joint Venture (JV), a property development partnership entity between Matome Maponya Investments (MMI), a black-economic empowerment property-investment company, and a family-investment trust.

Meanwhile, this development is also in line with the municipality’s Spatial Development Framework and Integrated Development Plan, which prioritise the need to accelerate the development of middle-income housing in this growing urban node.

CoreSlab, a leading precast concrete specialist, is also closely associated with this project. Its high quality precast concrete systems, including prestressed hollow-core slabs, have been extensively specified by architects, building contractors and developers for their projects.

According to Clifford Mogale, a project manager for CoreSlab, the company has been involved in about 80% of the home buildingprojects in Serala View. This is in addition to other growth nodes in-and-around the city and elsewhere in Limpopo. All are multi-storey projects, where the company’s hollow-core slabs have been used to rapidly construct the second floor of the structure.

However, it is the technology’s ability to significantly reduce project-related risk for smaller home-building teams and project owners that has also led to a preference for hollow-core

slabs versus other precast concrete technologies.

The accurate installation of the precast concrete hollow-core slabs is undertaken by CoreSlab’s own skilled team. CoreSlab’s expertise spans the timely transportation of the elements from the company’s state-of-the-art factory in Polokwane to site. The use of its own cranes plus operator and riggers also ensures the safe lifting and efficient placement of each concrete “plank”.

“While the residential market has and will always be a major focus for us, we have also been extensively involved in other large projects, which has allowed us to refine this capability. This includes projects ranging from malls to hotels, as well as state-sponsored infrastructure programmes. They too have significantly accelerated and reduced risk on their projects by using our precast concrete systems,” Mogale says.